Accelerate new linear infrastructure route development - with confidence

Enable faster, lower-risk and more sustainable project development, from concept to consent, with one powerful cloud-based optioneering platform.

Streamline optioneering in one platform

Cut programme length

Undertake comprehensive route selection

Build consensus with key stakeholders

Who We Serve

End-To-End Workflow

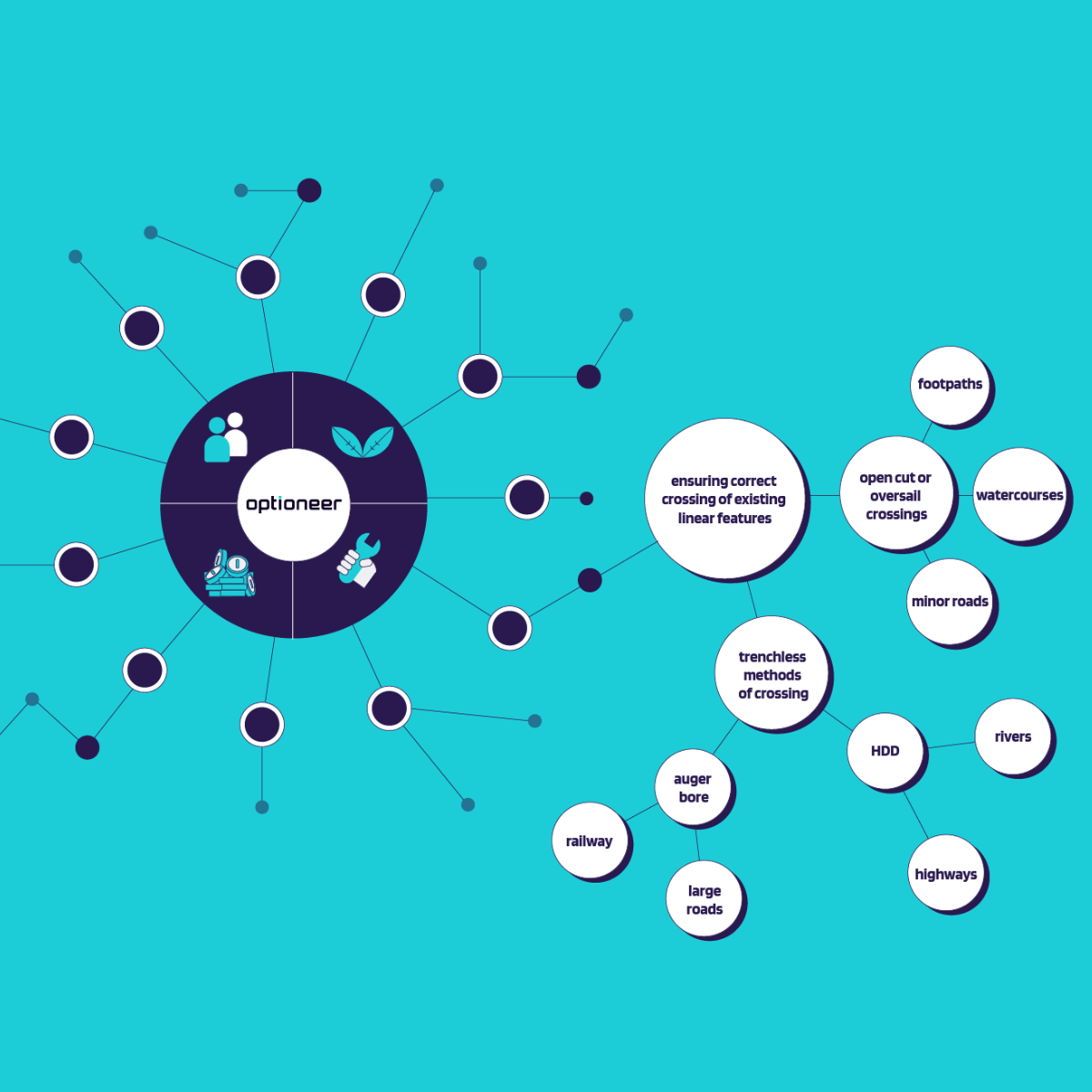

Optioneer Engine

Save time by automating route analysis for dozens of potential scenarios, with detailed assessments against social, environmental, engineering and cost criteria. Undertake a more robust route selection process which you can complete in weeks, not months.

Supported assessment of over 40,000 km of assets

Average reduction in time to complete initial route development and evaluation

Number of countries where Optioneer has been deployed

World-class technology

Streamline your project development programmes in the cloud

Prepare better route applications for your infrastructure programme with intelligent, digitised route optioneering. Make instant updates to route scenarios, create a single source of truth on all route data and decision making, and develop a more collaborative process for your team that also involves key external stakeholders earlier on.

Discover how Optioneer can help you:

We will be in touch with you shortly.

.jpeg)